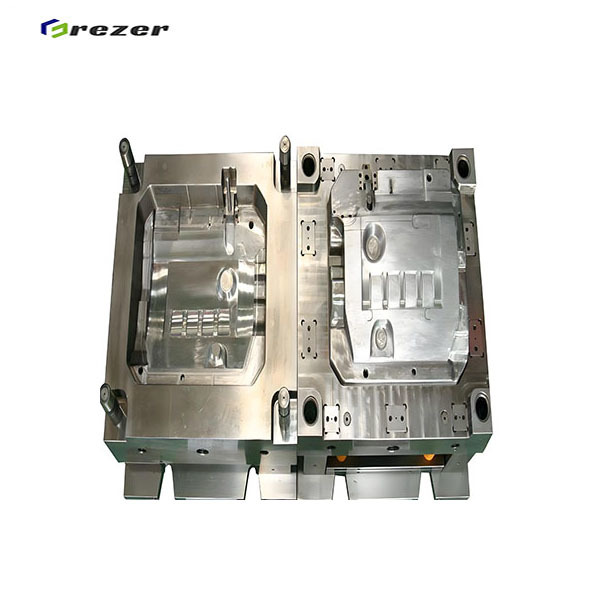

ODM High Precision H13 Steel Aluminum Die Casting Mold Mould

Product Introduction

This die-casting mold utilizes premium H13 hot work die steel as

its base material, integrated with a variety of precision machining

procedures and tailored surface treatment techniques. It is highly

adaptable to the die-casting production requirements of diverse

metal materials like aluminum alloy and magnesium alloy. In

response to the variations in melting points and fluidity among

different alloys, the mold is fitted with an adaptive temperature

control system and a refined runner configuration, enabling precise

regulation of the metal melt's filling rate and solidification

process. This effectively mitigates common casting flaws such as

porosity, shrinkage, and distortion, guaranteeing that the

casting's surface smoothness, dimensional precision, and mechanical

performance adhere to consistent standards, thus meeting the

high-end manufacturing demands of sectors including automotive,

electronics, and home appliances.

The mold’s design is fully optimized for mass production

environments, boasting an efficient cooling circuit and an

intelligent ventilation system. This not only shortens casting

cycles but also diminishes thermal fatigue damage to the mold,

prolonging its service life and substantially reducing enterprises’

unit production costs. Based on clients’ specific casting

blueprints and production conditions, we provide comprehensive

customization services, offering a one-stop solution encompassing

mold structure optimization, mold flow analysis, and trial mold

debugging.

Product Specification

| Mold Material | Diecasing Frequency(Approx.) |

| H13 | 45000 |

| 8418 | 75000 |

| Dievar | 100000 |

Product Show

Our team

Our team are professional in service and quality control to give

you the assurance of the pleased purchasing experience and the

aftermarket service. Our mission is “ good service, good quality’,

depend on more than 20 years experience to give you the solution to

meet your requirements.

Choose Us

- Professional design team

- Reliable quality

- Excellent service

- One year quality warranty

Transaction Process

- Custom manufacturing based on provided drawings and samples

- Receiving your payment

- Design drawing confirmation

- Sample confirmation

- Production and inspection.

- Packing

- Delivery

Packing

Ship in wooden crates to ensure product integrity.

FAQ

Q1: Do you support customization?

Yes.

Q2: What is the production time?

Normally one week after receiving your payment.

Q3: What is your minimum order quantity?

MOQ 1 set.

Q4: Are you a manufacturer?

Yes.

Q5: Which delivery methods can you support?

By air, sea, land, rail, express like DHL, UPS, FEDEX.